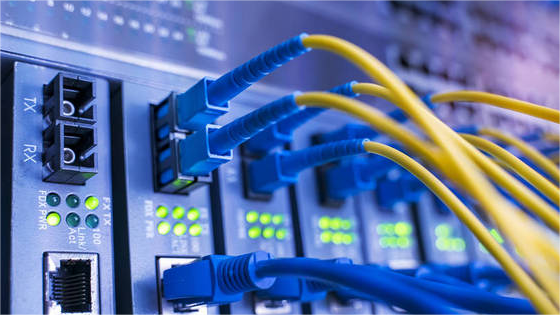

Fiber optic patch cords play a crucial role in ensuring reliable data transmission in telecommunications and networking environments. To guarantee their performance and longevity, it’s essential to conduct thorough testing, understand their interface types, and maintain them properly. This article explores four key tests for fiber optic patch cords and provides guidelines on their usage and maintenance.

Tests:

1.Visual Inspection: Visual inspection is the first step in assessing fiber optic patch cords. It involves checking for any physical damage, such as cracks, bends, or contaminants on connectors. The inspection also verifies proper alignment and cleanliness of connectors, ensuring optimal light transmission. Use a fiber optic inspection microscope and fiber optic cleaning tools to perform this inspection regularly.

2. Continuity Test: The continuity test verifies that there is an unbroken path for the optical signal through the fiber optic patch cord. It ensures that each fiber strand is properly connected and that there are no breaks or short circuits. This test is typically performed using a fiber optic continuity tester or an optical time domain reflectometer (OTDR) for more comprehensive analysis over longer distances.

3. Insertion Loss Test: Insertion loss testing measures the amount of signal loss when light passes through the fiber optic patch cord and connectors. It evaluates the quality of the connectors and splices by quantifying the amount of light that is lost due to absorption, scattering, or reflection. Use a light source and power meter (LSPM) to conduct insertion loss tests accurately.

4. Return Loss Test: Return loss, also known as reflectance, measures the amount of light reflected back toward the source due to imperfections in the fiber optic patch cord connectors. High return loss can degrade signal quality and affect network performance. A fiber optic reflectometer or OTDR can assess return loss by analyzing the amount of reflected light relative to the incident light.

Usage and Maintenance Guidelines:

Proper Handling: Always handle fiber optic patch cords with care to avoid bending beyond their minimum bend radius and protect connectors from dust and contaminants.

Regular Cleaning: Clean connectors using lint-free wipes and appropriate cleaning solutions to maintain optimal performance.

Labeling and Documentation: Label patch cords according to their intended use and document test results and maintenance activities for reference.

Environmental Considerations: Keep patch cords away from extreme temperatures, humidity, and physical stress to prevent damage.

In conclusion, ensuring the interface type and quality of fiber optic patch cords involves performing visual inspections, continuity tests, insertion loss tests, and return loss tests. Regular testing, proper usage, and maintenance are essential for maximizing the lifespan and reliability of fiber optic patch cords in telecommunications and networking applications.

By following these guidelines and conducting regular tests, network administrators and technicians can ensure seamless data transmission and minimize downtime due to patch cord failures.